Brief note before you start: if you experience issues while assembling, installing or operating swapmod, please consider joining our swapmod discord server as this is the fastest way to get help from our support moderators or community members. Just click here to get your invitation.

Step 1: Download and print

Please download the files linked below and open in Bambu Studio or Orca Slicer. Please note, that all parts should be printed with 0.4mm nozzle!

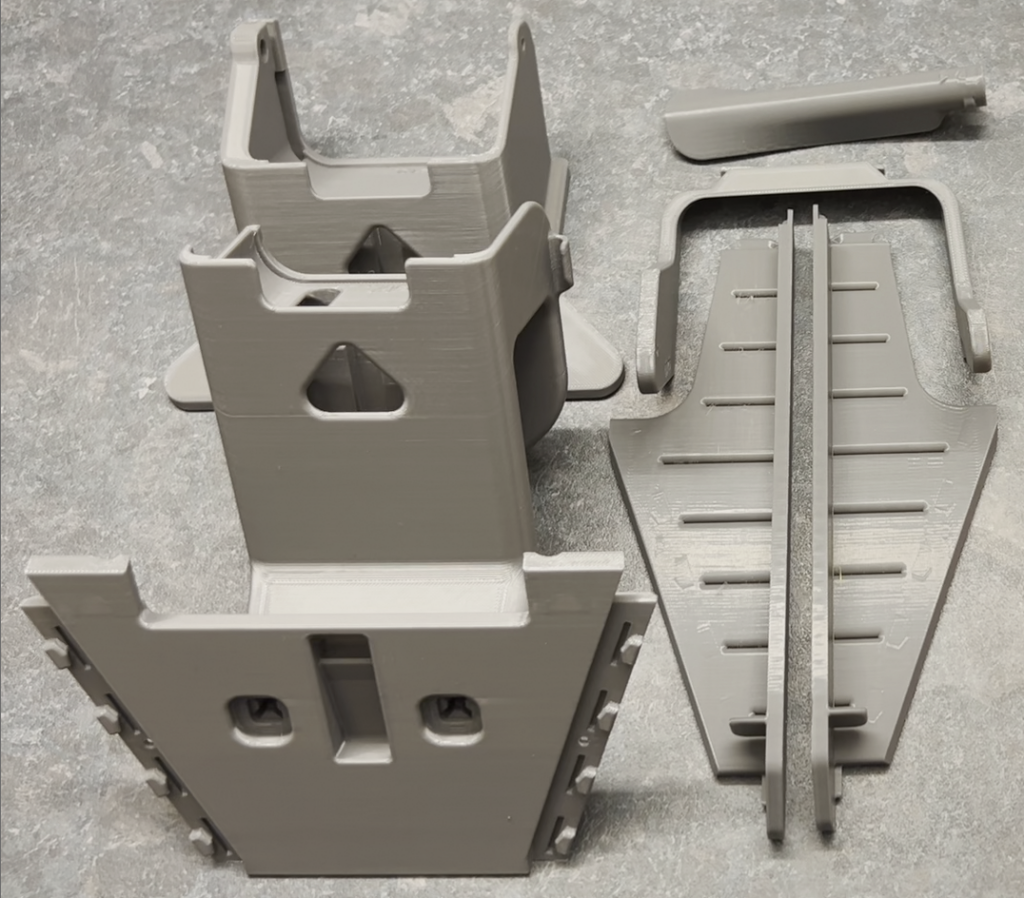

You can print this six parts directly on you A1 mini which will use 3 plates or print it on a larger printer (A1/P1/X1) where all six parts can fit onto one plate. It is recommended to use regular PLA (of any brand). Approximately 300g of filament will be needed.

Download swapmod A1M – public parts

Download swapmod A1M – plate hook

Print this plate hook in needed quantity using a regular PETG. Approximately 11g of filament will be needed.

After all parts contained in the files where printed and exempt from brim (if used) you can proceed with the assembly. Make sure none of these parts are warped or affected by stringing.

Step 2: Assembling swapmod A1M

Please check your Kit and make sure none of the parts which should be provided within a kit are missed. To assemble the kit you would need a 2mm (5/64″) hex key (you can find one in your BambuLab A1 Mini tool-box) and a regular Phillips screwdriver.

Now watch the video and repeat carefully all steps. It’s recommended watching the entire video first to gain an overview, and then watching it again while doing the assembly to follow along with the steps.

Make sure all parts fits well together without applying to much force. Also while fastening the screws you should not apply to much force in order to not accidentally break the threads. Especially when attaching ejector lifter, please make sure it still moving freely, like shown in the video.

Now when you complete with the assembly you can go on with the next guidance step which shows how prepare your build-plates, attach swapmod to your printer, perform a self-test and start using the system.

Step 3: Preparing build plates

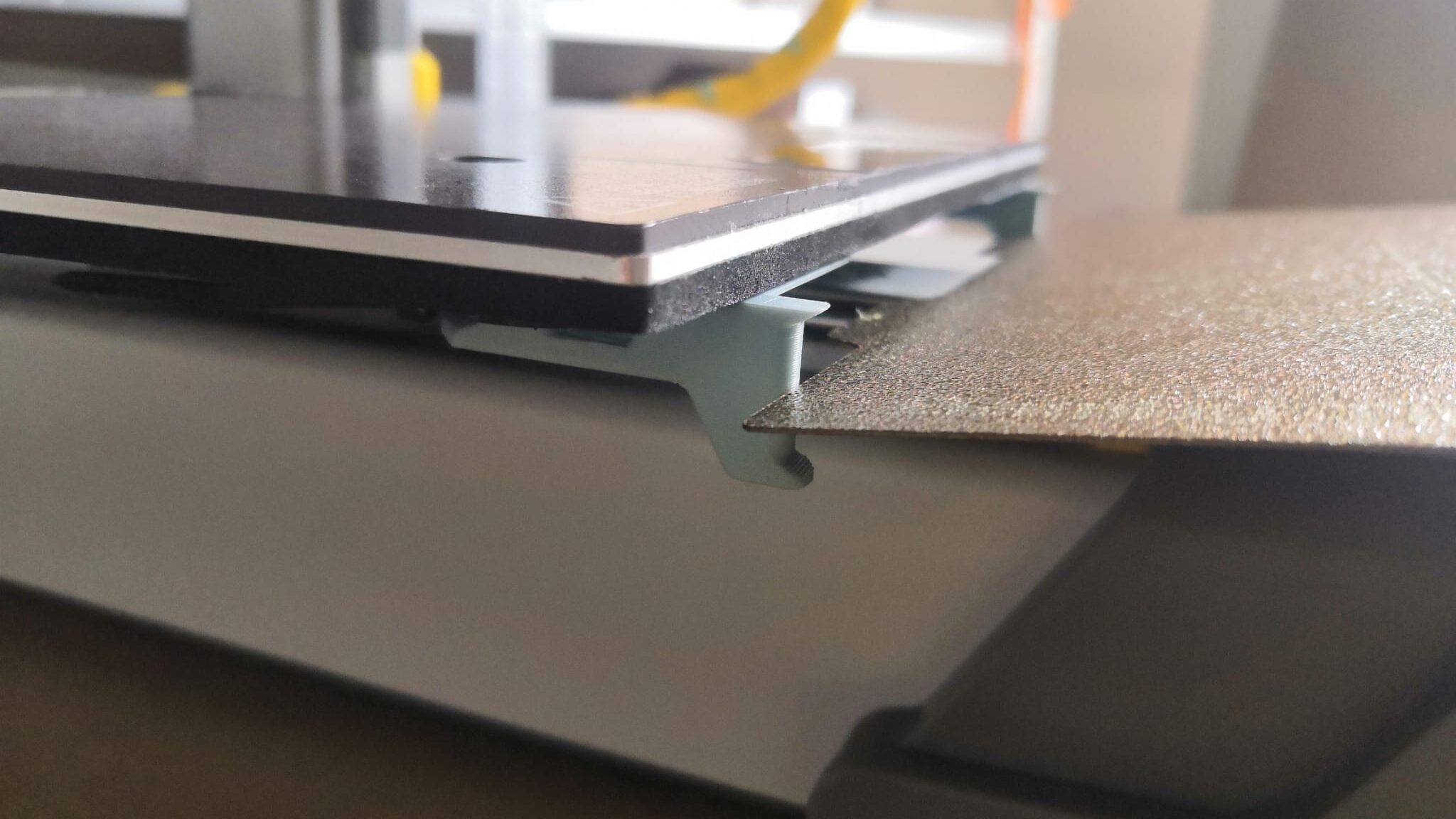

In this step you will learn how assemble the hook and attach it to the build plate.

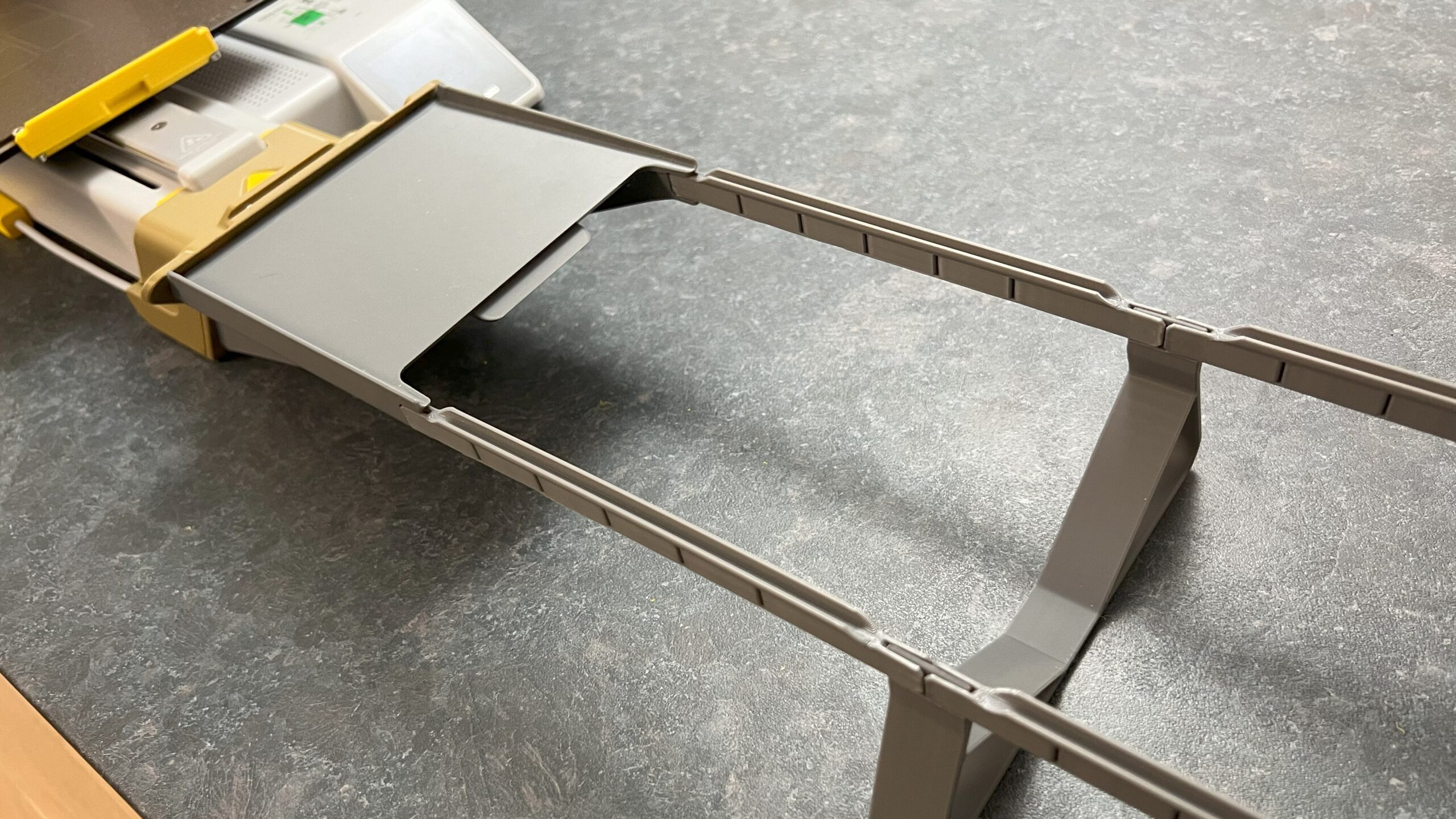

Step 4: Installing swapmod

In this step you will learn how to install swapmod on your BambuLab A1 Mini printer.

Step 5: Performing self-test

In this step you will learn how to run a self-test of swapmod. It is recommended that this test is carried out after the printer is in place in its actual work area.

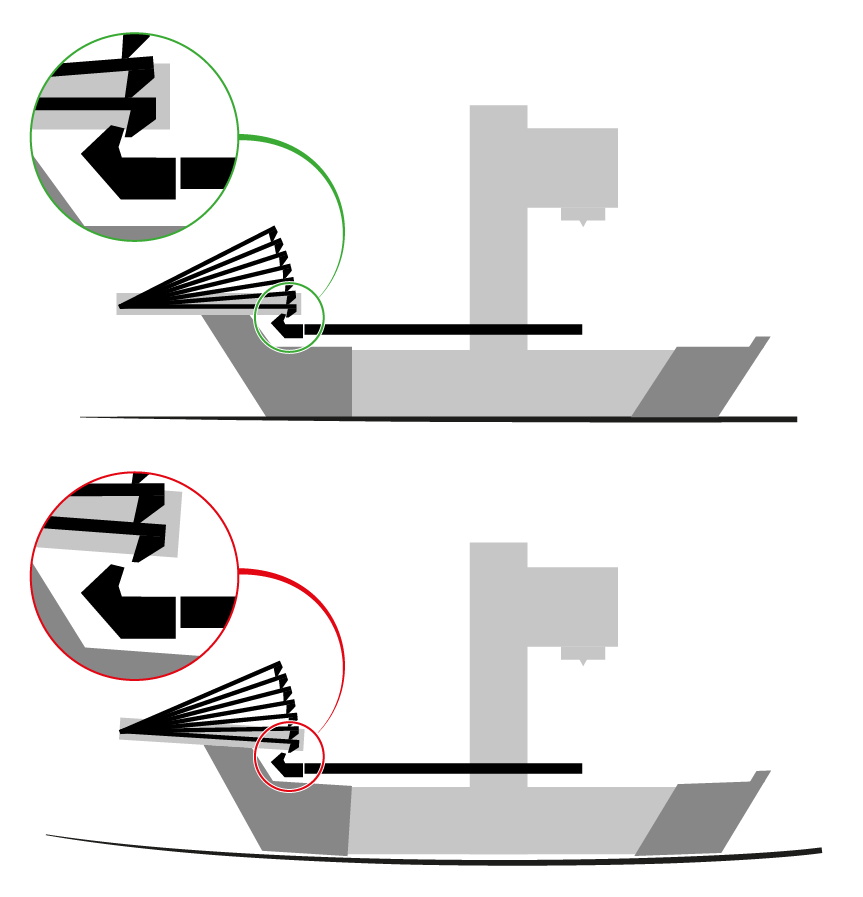

If you notice that loaded plates are always slightly rotated (see picture below), this may be due to the misalignment of the magazine.

In this case, you can counteract this by slightly adjusting the magazine’s orientation, as shown in the previous chapter.

Step 6: Using swaplist.app

In this step you will learn how to use swaplist.app to print multi plate projects.

Do NOT use your browser’s auto-translation function.

This will lead to malfunctions of swaplist.app.

Swaplist alternatives

Swaplist.app is our in-house developed low-tech solution which offers an easy understandable way to start with automated printing. However, depending on certain use-case this might possibly be not the best or most comfortable way for everyone. There are multiple alternatives and other possible ways on how you can use an automation. Please follow this link when you want learn more about possible alternatives like swapnow-file or printing-manager services.

Step 7: Using swapmod

Your system is now ready to use. Before you start, please read the following chapter, which will help you set up a workspace for your swapmod system and give you some tips and tricks.

Maintenance of the trigger rope

The trigger rope can loose tension over time or may not have been properly tensioned at the time of manufacture!* Loose rope might lead to problems during plate ejection (when the ejector lifter is not rised high enough to “catch” the plate hook).

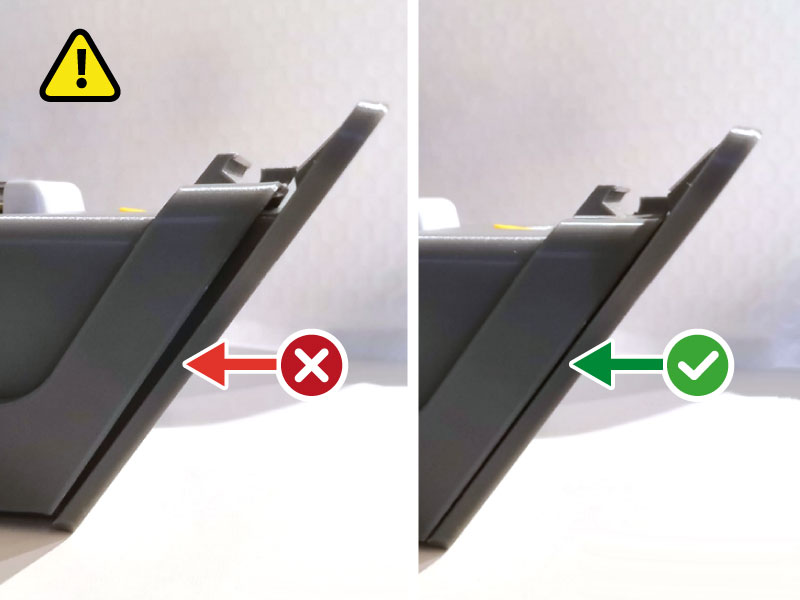

A loose rope can be identified by the gap under the trigger glider (see picture below).

To start tensioning the rope, pull the rope tensioner apart to unlock it (see picture below).

Then turn the screw (see picture above) until the gap under the trigger glider disappears (see picture below) or at least shrinks to less than 1mm.

Also make sure that you have NOT over-tightened the rope (see left picture above)! The ejector lifter should stay in a rest position (see right picture above).

*We do our best to check each kit and re-tension the rope if needed. However we noticed that even if the tension is set right during assembling, after first week in the shelf the rope lose some tension anyway. It might happen because the stress goes out of the material. We are investigating this phenomena and look for possible solutions in order to improve our quality management measures. But for now it is recommended checking the tension before first use and keep an eye on it.

Avoiding jams

As mentioned in the last part of the previous video you should avoid plate jams at the ejecting unit. This can be done by using a collecting box or extending ramp. Collecting box is a better solution, because in this way ejected plates will less likely cause any trouble.

However if you are operating within a limited area and collecting boxes are not an option, please use the plate pusher and extending ramp (optional) add-ons.

This additional parts (especially the pusher add-on !) will make sure your plates cause no jams by falling underneath the heat-bed during unloading.

You can also extend this ramp with optional rails if your prefer treat your ejected plates in the most secure and gentle way.

Place on flat surface

Please make sure that your system (printer and swapmod) is placed on a flat surface. This is very important for the correct operation of the swapmod add-on. As the magazine and ejector units are not firmly mounted to the housing of the printer, their relative heights will vary greatly depending on the surface on which they are placed. There is a margin of tolerance, but it is important to remember that uneven surfaces can cause problems during the loading and unloading process. Here is an illustration of how a concave shelf can affect the setup.

As you can see in the bottom picture, an uneven surface can raise the magazine so that the plate cannot be hooked by the heat-bed gripper.

That doesn’t mean that your swapmoded A1 mini has to be placed on a rigid concrete slab from now on. It can actually work on any surface. However, you will need to test your system after placing it on a certain surface to ensure that it still works, and if it does not, take appropriate action (e.g. use underlays or similar).

Avoid bumping the magazine

As mentioned before, magazine is not firmly bolted to the printer’s housing and can easily be twisted when accidentally bumped. Take this into account and keep an eye on the alignment when the magazine was accidantely moved.

Stopping the queue

As mentioned above, the queue generated by swaplis.app is not live editable. So when you need to remove or add a plate you will need to abort running queue. Sometimes you realize this while the print is running and you don’t want aborting it to not waste already spent material and printing time. In this case you can use a trick which will let the printer finish current plate but automatically force it to stop before starting the next print.

To do this, simply remove the plates from the magazine or turn the bottom plate in the stack upside down. This will prevent the printer from loading a plate and the printing process will stop as soon as your printer detects that there is no plate. Please note that plate detection must be enabled in the printer settings (it is actually enabled by default). Now your printer will wait for you before continuing.

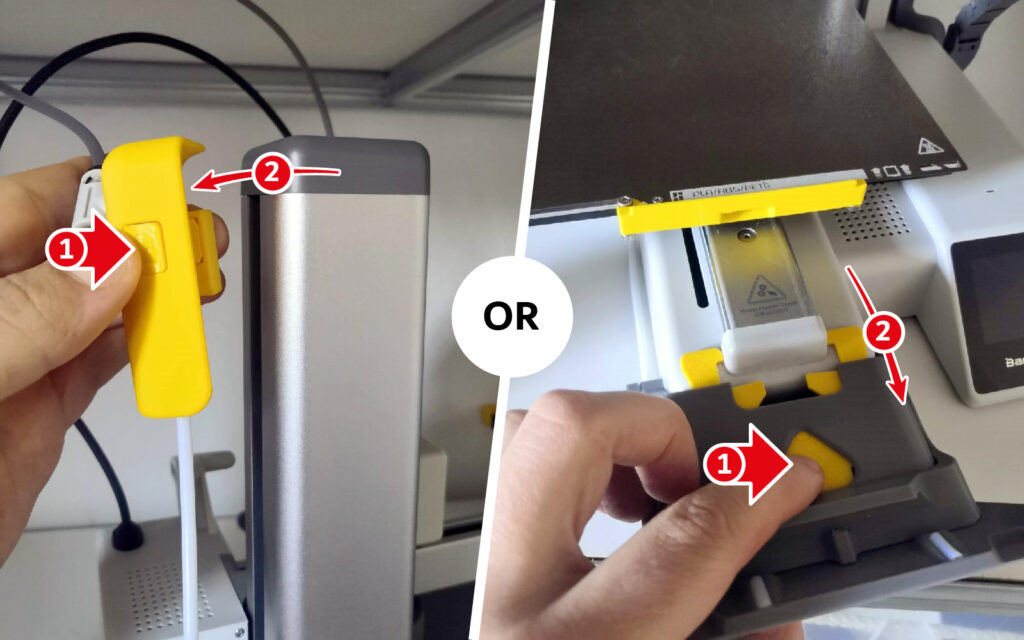

When swapmod is not in use

When you’re not using swapmod (that is, when you’re not printing queue files generated by swaplist.app), it’s recommended that you disconnect the eject trigger from the printer’s z-axis OR the entire ejector unit. Otherwise, your printer may accidentally eject the plate before printing. This happens especially if your printer has previously printed a tall object and you start a new print while the extruder is still in a high position.

Extend and mod swapmod

The ramp extender mentioned above is not the only accessory which was designed or adopted for use with swapmod. There is an official collection on makerworld where you will find other models which can be used with swapmod.

There is also a second collection containing famous third party models, where a swapmod-compatible profile were uploaded. Means if you want using one of these mods with swapmod, you need to look for “swapmod-compatible” printing profile.

Join community

If you would like to stay informed about swapomod and get in touch with developer and community, consider joining our discord server!

Troubleshooting

At some point in the future, there will be an ordered section here with the most common problems and the measures that will help to solve them. At the moment the support will mainly be provided at our discord server.

This is probably the fastest way to get help, because you will most likely find issues like yours which already have been solved and there is also a chance that you get advice by the community.

If you want go a classic way and contact support via email, you can do so by reaching out to support

swap-systems.com.

Please note, you will not receive any automated confirmation email and it can take few days before you get an answer. If you want share something, please use a cloud service to upload your pictures or video and send a link via email. Please don’t use attachments in your email. It is very likely that emails with attachments will be blocked by our system. Also please take into account that our official support languages are English or German. Emails in other languages will not be answered.

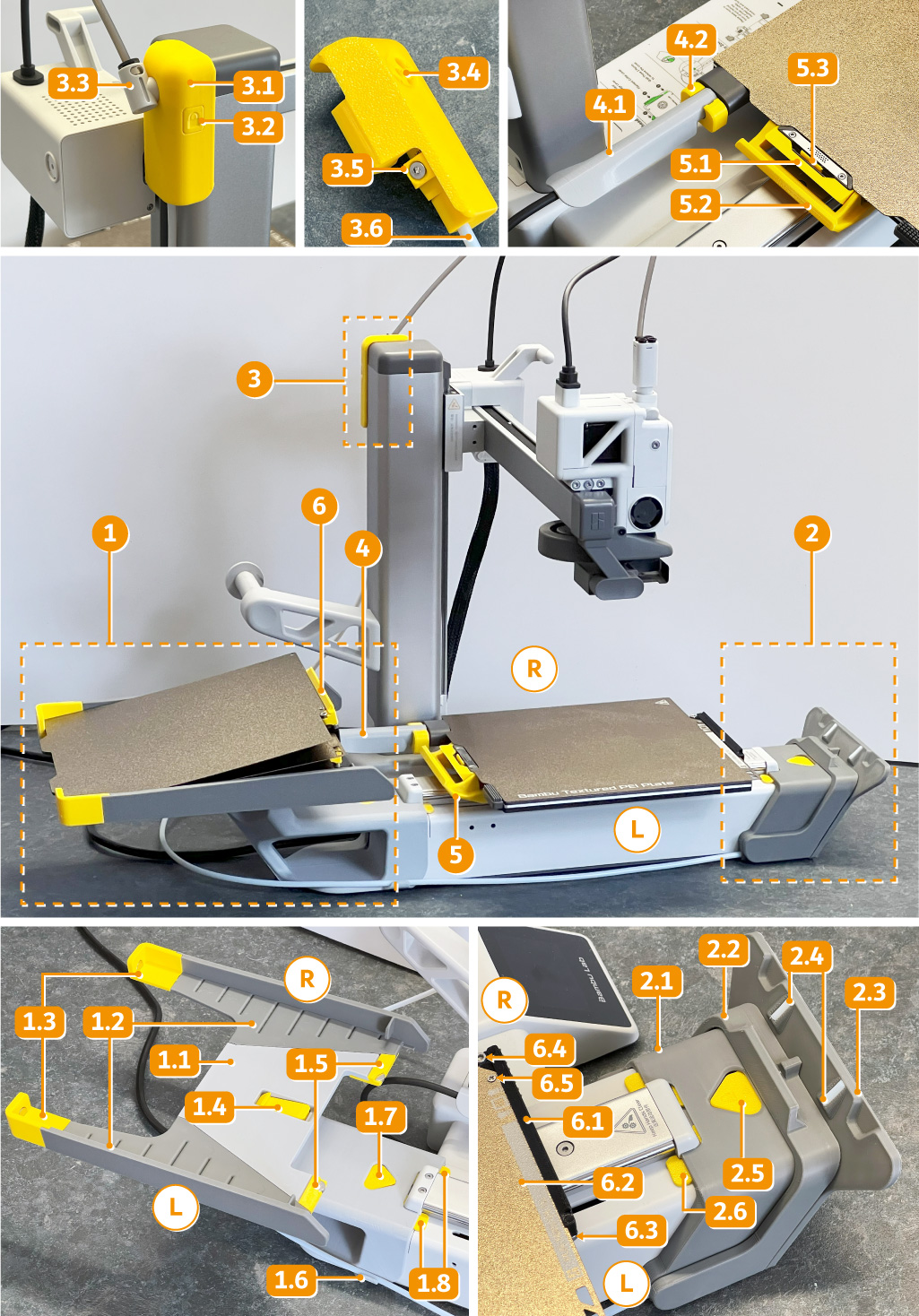

Part’s names reference

1. Magazine

1.2 Magazine body

1.2 Magazine sides (L/R)

1.3 Magazine rear stop(L/R)

1.4 Magazine middle stop

1.5 Magazine front stop (L/R)

1.6 Magazine tube-holder

1.7 Magazine lock-button

1.8 Magazine lock-gripper

2. Ejector

2.1 Ejector body

2.2 Ejector lifter

2.3 Ejector ramp

2.4 Ejector glider (L/R)

2.5 Ejector lock-button

2.6 Ejector lock-gripper

3. Trigger

3.1 Trigger body

3.2 Trigger lock-button

3.3 Filament-tube holder

3.4 Filament-tube holder slot

3.5 Trigger glider

3.6 Trigger-tube

4 Cable-guide

4.1 Cable-guide body

4.2 Cable-guide lock

5. Gripper

5.1 Gripper body

5.2 Gripper hook

5.3 Gripper snap-lock

6. Plate equipped with hook

6.1 Plate hook

6.2 Build plate

6.3 Plate hook stop screw (L/R)

6.4 Plate hook counter screw

6.5 Plate hook main screw